Service and maintenance of water slides

Our mission is to ensure the safety of water slide users.

We offer comprehensive water slide servicing – from minor on-site repairs to full renovation of the slide tube surface and splashdown pools. We eliminate common laminate damage such as cracks, osmosis, chipping, and leaks at element joints. We restore anti-slip coatings and replace worn connections between segments. Safety and guest satisfaction are our top priorities, which is why we take on even the most demanding challenges.

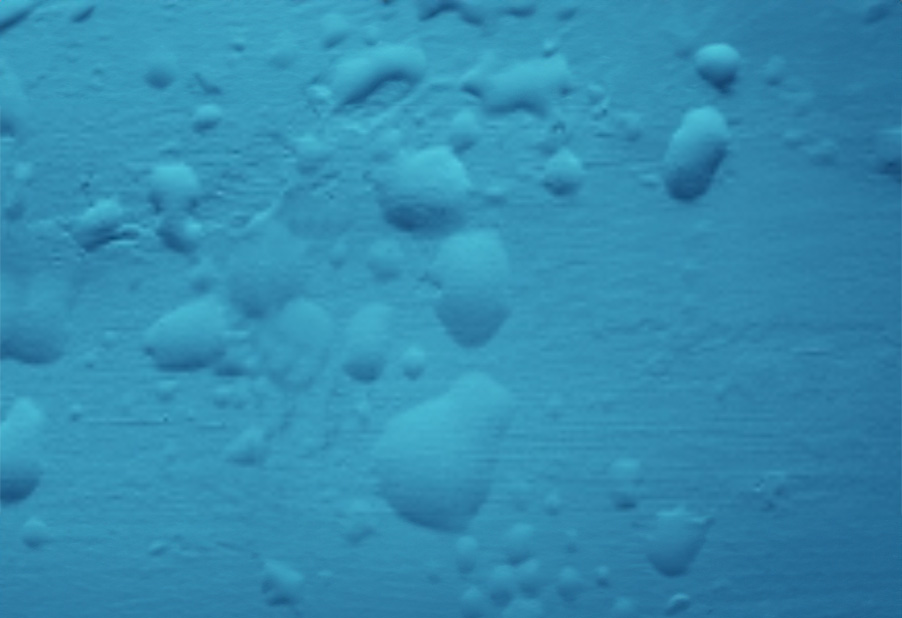

Photo: Osmosis – formation of osmotic blisters

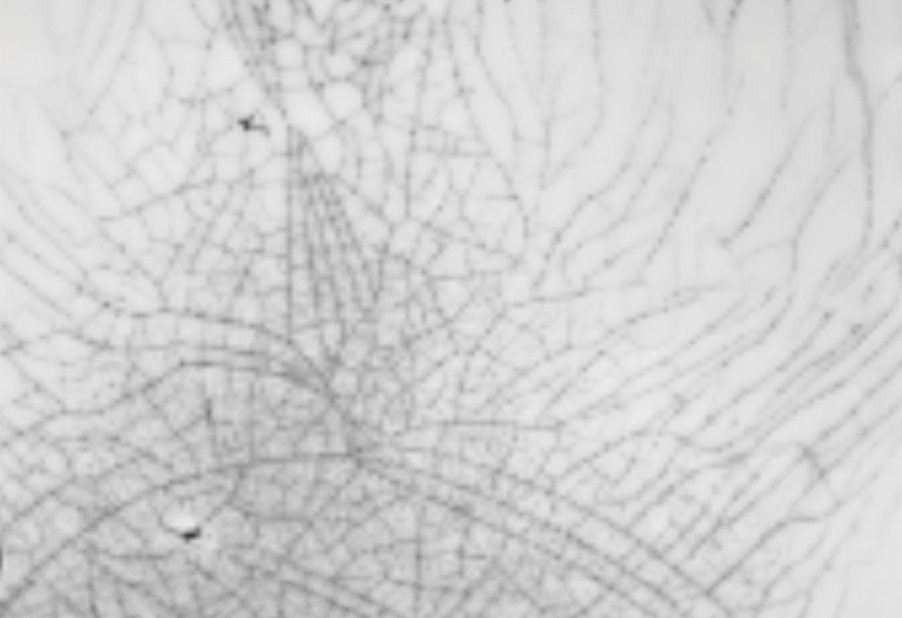

Photo: “Spider web” cracks – characteristic fractures in the laminate

Photo: Discoloration and deposits – surface staining, build-up, or fading

Laminate repair services

We provide a full range of laminate repair services, including diagnosis and defect removal.

Most common issues:

1. Deposits on the laminate surface:

the build-up of chlorine particles reduces aesthetics and sliding properties, decreasing the sliding speed.

2. Scratches and stains:

mechanical damage may lead to cracks and scratches, and even damage to swimwear.

3. Loss of anti-slip coating:

increases the risk of slipping and falling for users.

4. Discoloration and fading:

prolonged exposure to weather conditions damages the laminate and external coatings.

5. Osmotic blisters:

water in the micropores of the laminate forms blisters which, when they burst, leave sharp edges dangerous to the skin.

6. “Star-shaped” cracks:

result from manufacturing defects or mechanical damage; they may enlarge and pose a safety risk.

7. Gelcoat losses:

sharp edges require immediate repair.

8. Assembly errors:

poorly executed element joints are noticeable during the ride and must be repaired for safety.

Replacement of connections between slide elements

Connections between elements wear out and crumble over time. Their replacement is a key part of renovation.

We use different methods depending on the condition of the slide:

- New silicone joints fast, economical method for light wear; visible but fully functional.

- Hard joints (“seamless”) provide a smooth, uniform surface, invisible and unnoticeable to the user.

- Laminated joints the most durable option, reinforcing joints and adjacent surfaces; invisible and long-lasting.

Photo: New silicone joints

Photo: Hard (“seamless”) joints

Our techniques for renovating and replacing connections between water slide elements ensure that the slide remains safe, smooth, and visually appealing. We offer solutions tailored to the specific condition and needs of each water slide in order to achieve the best results and improve the user experience.

Steel structure service

The steel structure is a key component of every water slide. Regular maintenance ensures its stability and long-term durability.

Scope of services:

- visual inspection and diagnostics of load-bearing elements,

- assessment of technical condition and possible deformations,

- removal of corrosion and surface repair,

- anti-corrosion protection (e.g. protective coatings),

- inspection and replacement of bolted connections.

Our team:

We are a team of passionate professionals with over 23 years of experience in the construction and servicing of water slides. We have worked with the largest manufacturers in Europe, gaining the knowledge and skills necessary to carry out even the most demanding projects.

Our experience has taught us that success is not only about the quality of workmanship but also about attention to the smallest details and user safety. Thanks to this approach, we offer top-quality services that extend the lifespan of water slides and ensure their safe use for many years.

Materials:

We use only top-quality materials such as:

Ashland Maxguard, Buffa, Soudal.

Client | Scope of service activities | Date |

|---|---|---|

Aqua-Tur | Renovation of the splashdown pool | Szczecinek, Polska (06.2024) |

Arena | Maintenance of the structure under the splashdown pool, replacement of connections in the splashdown pool | Żagań, Polska (09.2024) |

CW Laguna | Replacement of connections between Black Hole slide elements with hard joints, elimination of laminate chipping, removal of osmotic blisters, refurbishment of the starting element in the U-slide, and replacement of the connection with a laminated one, technical inspection of the slide | Gryfino, Polska (09.2024) |

Vistula park | replacement of soft joints, removal of cracks and laminate chipping, removal of osmotic blisters | Świecie, Polska (09.2024) |

Baltic Park Molo | Technical inspection of four water slides | Świnoujście, Polska (09.2024) |

Contact

Mariusz Grzechowiak

Details

- +49 39754 563571

- +48 662 194 168

- office@plastim.eu

Our address

Springweg 2

17321 Plöwen